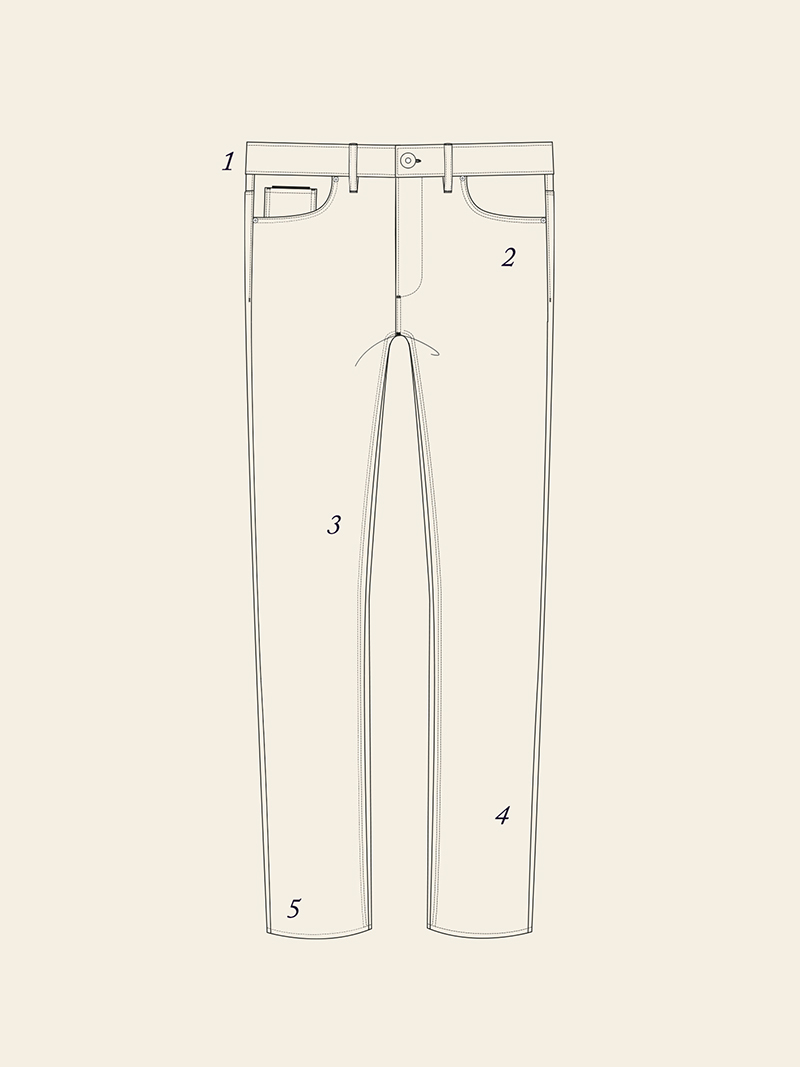

1. A high waistline for a slim silhouette.

2. A fitted waistband and waistband, so that pants fit well even without a waistband.

3. A straight leg that's neither too slim nor too wide: the thigh is comfortable to walk in without the jeans looking constricting. Pleats don't show too much behind the knees.

4. Pants that don't pinch the calf.

5. Letting the right leg fall with aplomb allows you to better control your trouser bottoms: slightly drooping over the shoe, worn a little short or rolled up.

All our jeans are cut and assembled in a single Italian workshop before being washed to achieve the desired shade, and we work with 3 mills:

Candiani: Candiani's selvedge fabrics are considered to represent the original denim, thanks to shuttle looms from the 1960s. Today, the company is a model of sustainable production, recognized as the most virtuous in its field.

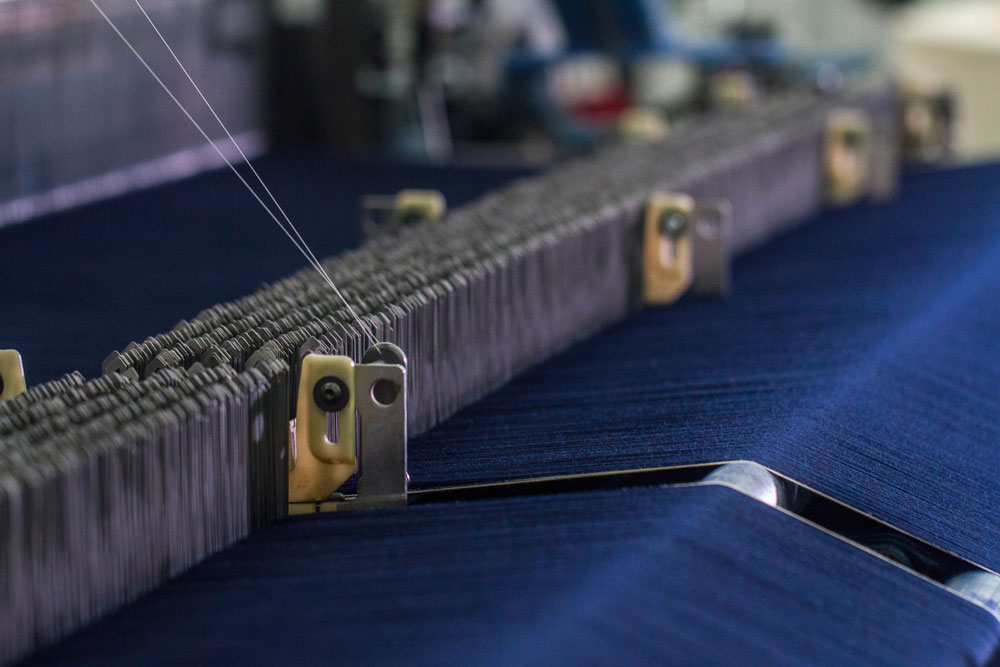

Blue Selvedge: Blue Selvedge fabrics are produced on Picanol shuttle machines, mechanical beauties from the 1950s, restored and renovated by specialized craftsmen who have lovingly maintained them to preserve their weaving technique.

Kuroki: The Kuroki spinning mill invents and produces fabrics as rare as they are coveted for their Made in Japan indigo dyeing. To produce the most beautiful colors and feel, Kuroki uses local soft water particularly suited to indigo dyeing for denim.

Made in Italy production, with know-how dedicated to making top-of-the-range jeans with meticulous traditional finishes.

Rivets, reinforced belt loops, Riri metal buttons

Selvedge trim on inside leg, and coin pocket corners

.

Chain stitch

Brut for purists who like these are rigid canvases that will hold up very well over time.

Stretch for those seeking comfort above all.

Washed or washed in the workshop: immediate comfort and limited shrinkage.

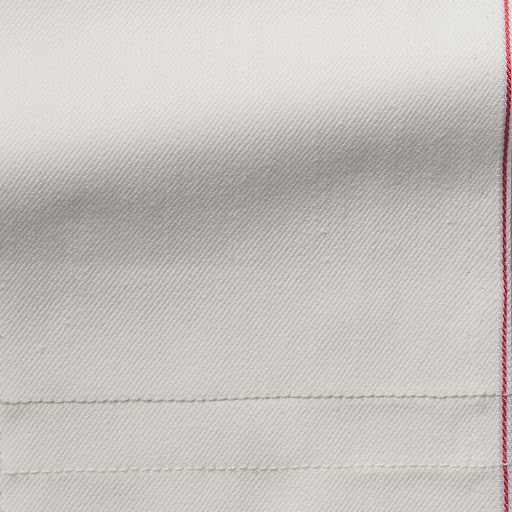

We offer classic selvedge in indigo blue and gray, woven in a 3x1 weave by Candiani in Italy. With a weight of 13oz, these are stiff weaves that will hold up very well over time.

For purists and lovers of thicker fabrics, we have a Japanese version from weaver Kuroki. Woven on ancient looms, the denim is heavy (14oz) and its very dark blue color is slightly grainy. Small imperfections that make this fabric sublime !

For those looking for comfort above all else, we have selected, again at Candiani, more or less faded toils, woven with stretch (in 12oz weights).

To complete our range of colors, we turned to Blue Selvedge (Italy) to offer white and black denim fabrics, in a lightweight, stretch version (11oz).

For a distressed look, some of our jeans are washed or faded in our workshop as soon as they arrive.

This guarantees immediate comfort and also limits the shrinkage that denim might undergo when new.

Nimes was an important textile region in the 18th century, particularly for materials such as serge and cloth. Twill referred to any type of woollen, semi-woollen or silk fabric made with a twill weave. Denim is therefore thought to be an abbreviation of “de Nîmes”.

Denim is therefore a robust cotton twill fabric characterized by a 3×1 warp weave: the weft passes under two warp threads, producing the famous diagonal ribs identifiable on the reverse side of the fabric. Traditionally, denim is made with indigo-dyed yarns for the warp and natural (or more often bleached) yarns for the weft.

Denim gained popularity in 1873 when Jacob Davis, a tailor from Nevada, produced the first pair of denim pants “reinforced with rivets”. It wasn't until the 1950s that the word “jeans” really came to designate this specific garment: denim pants with familiar features such as ochre stitching threads, rivets, five pockets and stitched back pockets.

The word selvedge (in British English) refers to the narrow, tightly-stitched border that finishes the edges of a width of fabric produced on an old-fashioned shuttle loom. The edging is usually white with a colored thread in the middle, a color originally added by manufacturers to distinguish the different qualities intended for their customers.

Selvedge fabrics are woven on narrow looms, which were replaced in the 70s and 80s by wider, more efficient looms.

Although slower, older looms produce more natural irregularities on the denim surface. These irregularities are enhanced by the use of washes and wear, creating finishes with a special relief and a much stronger character.